![]() 압력 분포 측정기

압력 분포 측정기

|

|

|

|

|

|

|

|

|

|

|

|

PRESSUREX (Fuji Prescale Film) |

|

압력과 압력분포를 보여 주는 압력 측정용 필름으로 압력을 받으면 필름이 적색으로 착색되며 압력의 크기는 착색 농도의 차이로 나타나게 됩니다. 측정 압력의 범위에 따라 적당한 종류의 필름을 선택하여 적용할 수 있습니다. |

필름의 종류 |

압력 측정 범위 (PSI) |

규격W (mm) x L (m) |

필름 타입 |

극저압(Ultra Low) |

28∼85 |

270 x 4 |

Two-sheet |

초저압 (Super Low) |

70∼350 |

270 x 5 |

Two-sheet |

저 압 (Low) |

350∼1,400 |

270 x 10 |

Two-sheet |

중 압 (Medium) |

1,400∼7,100 |

270 x 10 |

Single-sheet |

고 압 (High) |

7,100∼18,500 |

270 x 10 |

Single-sheet |

☞ 필름의 폭과 길이는 적용 용도에 따라 맞춤 주문이 가능합니다.

TOPAQ (Pressure Analysis System) |

TOPAQ Force Analysis System은 기 착색된 필름(PRESSUREX)을 이용하여 접촉면에 가해진 압력의 크기 및 분포를 분석하는 장비로 필름의 데이터를 읽는 스캐너와 분석용 소프트웨어로 구성되어 있습니다. |

TOPAQ Scanner |

|

|

TOPAQ Software (소프트웨어) |

|||||

스캐너를 통해 읽혀진 필름의 데이터를 이용하여 Windows 환경하에서 사용하는 소프트웨어로 아래와 같은 특징을 가집니다. |

|||||

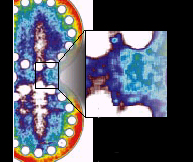

1. |

압력 분포를 칼라 맵(Color Map)으로 나타내줍니다. |

||||

|

|

|

|

|

|

|

착색된 필름 |

|

칼라 맵 |

|

|

2. |

등압 분포를 3차원 이미지 및 도표로 나타낼 수 있습니다. |

||||

|

|

|

|

|

|

|

착색된 필름 |

|

3차원 등압도 |

|

압력 히스토그램 |

3. |

Line Scan을 통해 특정선 상의 압력 분포를 확인할 수 있습니다. |

|||

|

|

|

|

|

|

칼라 맵 |

|

스캔 데이터 |

|

4. |

영역을 분할하여 특정 영역의 압력 분포 데이터(최고값, 최저값, 평균값 등)를 확인할 수 있습니다. |

|||

|

|

|

|

|

|

칼라 맵 |

|

압력 분포 데이터 |

|

5. |

특정 구역을 축소 및 확대하여 볼 수 있습니다. |

||

|

|

|

|

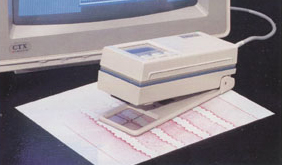

Point Scan (Pressurex Measurement System) |

Point Scan Pressurex Measurement System은 기 착색된 필름(PRESSUREX)의 미소 부위에 대한 압력 크기를 측정하는 간편한 장비로 스캐너의 기능을 하는 Densiometer와 분석용 소프트웨어로 구성되어 있습니다. |

|

|

컴퓨터에 온도, 습도, 필름 종류 등의 자료를 입력한 후 Densiometer를 착색된 필름(PRESSUREX)의 특정 부위에 올려 놓고 누르면 그 부위의 압력값이 자동으로 모니터에 나타나게 됩니다. |

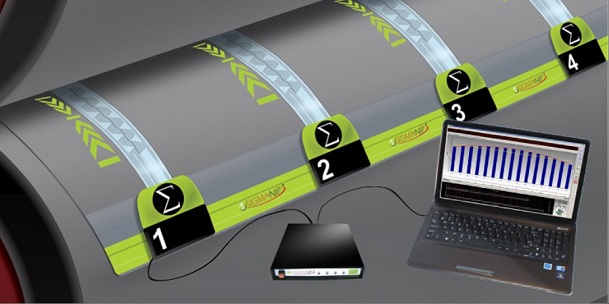

Nip 분석시스템 |

Roll과 Roll 또는 Roll과 평판이 접촉하면서 형성되는 Nip을 분석하여 Roll의 Crowning 및 Parallelism을 확인하고 최적의 Nip을 얻을 수 있는 자료를 제공하는 장비로 다양한 형태의 센서를 제공하고 있습니다. |

|

Auto-Nis |

|

압력 측정용 필름을 이용하여 Roll과 Roll 또는 Roll과 평판 간 접촉부의 Nip 자료를 얻은 후, 이를 Scanner로 읽어 전용 소프트웨어로 분석하게 됩니다. |

|

|

|

|

DigiNip |

|

단자형의 센서를 이용하여 Roll과 Roll 또는 Roll과 평판 간 접촉부 중 원하는 곳의 Nip을 타 부위Nip과 신속하고 정확하게 비교할 수 있는 장비로, 센서가 방수 처리되어 생산 현장에서도 바로 Nip 분석이 가능합니다. |

|

Sigma-Nip |

|

단일정 간격으로 나열된 Nip 센서 시트를 Roll 표면에 부착하여 Roll과 Roll 또는 Roll과 평판 간 부위별 Nip 폭을 실시간으로 분석할 수 있는 장비로, 정지 상태로 Roll을 정렬하는데 적용합니다. |

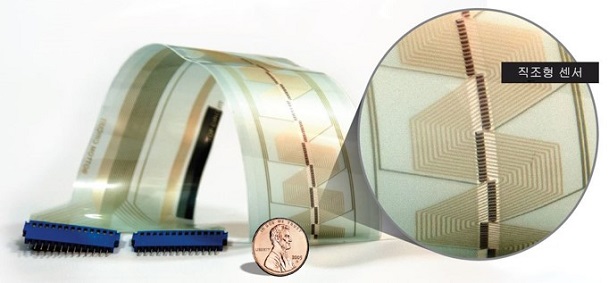

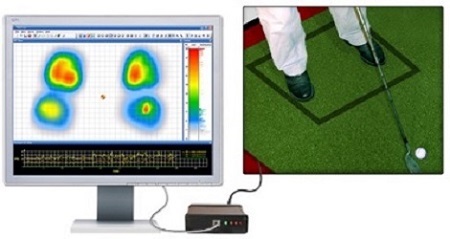

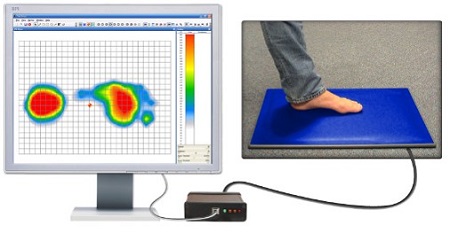

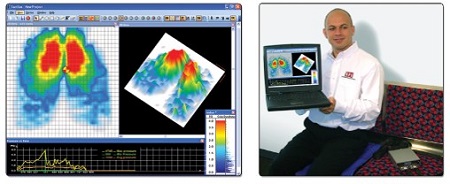

TACTILUS (실시간 압력 측정 시스템) |

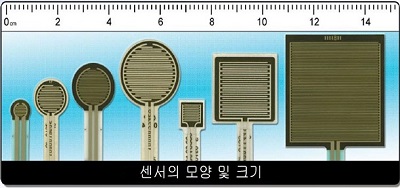

TACTILUS는 패드형 또는 단자형의 압력 지시 센서를 이용하여 접촉 압력의 크기 및 분포를 실시간으로 측정하고 모니터링 할 수 있는 장비로 다양한 형상과 크기 및 압력 범위를 가지는 센서를 제공하며 주문 제작형의 센서도 제공합니다. |

|

|

|

|

Gasket |

Nip Impression |

Tire Tread |

Foot Impression |

|

TACTILUS R-Series | ||||||||||||

| ||||||||||||

|

TACTILUS H-Series | |||||||||||||||

|

|

| ||||||||||||||

|

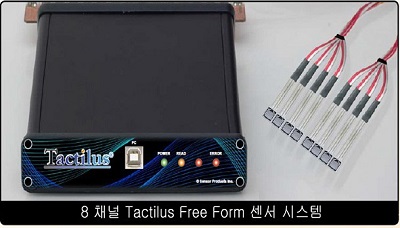

TACTILUS Free Form Sensor System | |

|

단자형의 센서로 최대 16개의 센서를 원하는 부위에 부착하여 접촉 압력의 크기를 실시간으로 측정하고 모니터링 할 수 있는 장비입니다. | |

|

측정 압력 범위 |

0 ~ 28.1 Kg/cm2

최소 센서 두께 0.36mm 측정 정밀도 ±10%

사용 온도 범위 0 ~ 45°C

|